Website content

This category is for website development and improvement for QIPstart

Top of the Improvement Pops Volume 1

Welcome to our latest blog. We have searched high and low for some musical inspiration to share some desired (and less desired) improvement behaviours. Hope you enjoy our Top 20 Improvement songs, why don’t you play the track to remind you next time you encounter one these below. Enjoy!

If you have a few more tracks for your own Improvement Top 20 – let’s start Volume 2… drop us a line!

At Number 20. We don’t need another hero – Tina Turner

Tina letting us know that healthcare improvements are far better in multi-disciplinary teams. Those inspiration figures leading without coaching support can sometimes lead to unstainable improvements. And what happens when they leave?

In at 19… You’re So Vain by Carly Simon

Carly has seen a few of these. The leader/team manager who ‘knows it all’, keen to shoehorn their ‘experienced views’ whilst ‘practicing’ improvement. Often lacking a few key coaching skills

Breaking through at No 18. On My Own, By Pattie LaBelle and Michael Mcdonald

That training curriculum deadline looms. Not got time to get an improvement team together, too embarrassed to join a team so late? Nothing like doing a low-hanging fruit unstainable QI by yourself, As Pattie says ‘this wasn’t how it was supposed to be.’

In at 17. I heard it through the grape vine, by the legendary Marvin Gaye

All too common this one. Marvin in his own unique way describes the risk of relying on anecdotes and hearsay to formulate improvement aims. No proper measurements at baseline either. Oh no!

At 16, Thinking Out Loud, its Mr Ed Sheeran!

In the charts for a while now… Ed knows that it is important to brainstorm so to ‘understand the problem’ better. When not playing his guitar, he has a secret stash of sticky notes for a quick process map or fishbone to use with his improvement team.

Staying at 15, More than words, Extreme.

Don’t write pages when a few will do. Show your understanding, designs and measurements with a few choice improvement figures and run charts. Put it all together in an A3! It may engage more people than a business unit report…

A solid 14 for… Islands In The Stream, Kenny Rogers and Dolly Parton

Kenny and Dolly talk about the importance of sharing and scaling improvements properly through well designed quality management systems. Just how many isolated ward based sepsis programmes does a Trust need?

At 13, Livin’ on a Prayer, Bon Jovi.

Yep, you guessed it, random unevidenced interventions. Playing whac-a-mole until something sticks, usually under the cloud of operational pressures. Definitely ‘Livin’ on a prayer’.

Falling sharply at Number 12. Money for Nothing. Dire Straits.

Dire Straits wants you to know about starting small with your PDSAs. Don’t waste staff time and money on large scale PDSAs from the outset. Unless you want to print out 500 copies again of the wrong proforma again. There goes the budget!

Another steep drop at 11. Another one bites the dust by Queen

Freddie Mercury tells us of those Plan-Do-Study-Act cycles, where we just keep abandoning ideas because they ‘haven’t worked’. Forgetting to predict what happens in the planning phase, not taking the time to study or learn from each PDSA cycle.

Clinging on to No 10. Sitting on the dock of the bay by Otis reading

Otis is looking back on all those procrastinators and perfectionists who seem to take an eternity to move their improvements forward. Waiting for their data to come through (not SMART!), or waiting for that all important improvement team meeting in 3 months…

Up to Number 9. Shake it off by Taylor Swift.

Taylors in on it too. Just like in the Survivor track. No PDSA is a ‘bad’ PDSA. So if the PDSA doesn’t meet your prediction, learn from it and ‘shake it off’.

Straight in at number 8. Eye of the Tiger. Survivor

Put on this banging track to keep you working towards your improvement aim. Filled with resilience and perseverance, you may have some set backs, but with all that learning, you and your team will get there!

Going up to 7. Another Brick in the Wall. Pink Floyd

Pink Floyd appreciates that some improvements face many obstacles. The trick is to remove one brick at a time by breaking larger problems into smaller ones.

Falling at Number 6. The only way is up. Yazz and The Plastic Population.

We’ve all been there, those serial baseline measurements values were even lower than expected. But on the plus side, this leaves more scope to improve. Over to you Yazz!

Coming up to 5… Counting Stars by One Republic

This band knows that if you don’t measure you cannot say you have improved. They do acknowledge however that counting stars may not meet the ‘relevance’ criteria in as a healthcare SMART measurement.

Strong showing at No 4. Tow out of three ain’t bad by Meat Loaf.

Meat Loaf gets ‘very angry’ with those improvers who set challenging improvement aims from a baseline of 20% all the way to 100% in one go, in complex healthcare environments. He says set achievable expectations. Get from 20% to a new baseline of 66%, as Meat Loaf says ‘Two out of three ain’t bad’. You can always set a new improvement aim in the future.

Staying high at number 3… Levitating by Dua Lipa

Dua understands that a trend upwards of 7 consecutive measurement points in a row rarely happens by chance! The probability of that happening is 1 in 128!

Go Dua!

At number 2. I’ll Stand by you. The Pretenders,

Last week’s number one song. Through thick and thin, your improvement coach will stand by you. Fail fast, learn quick. Don’t give up. No doubt, a coach who loves their job can guide you through the whole improvement experience.

Up one place to Number 1, we have… Take a Bow by Madonna.

Madonna wants to celebrate with you! A true improvement team effort. All the stakeholders involved (including patients), a real attempt to understand the problem, clear aims and SMART measurement, using PDSA for learning. Sustaining over time, evidenced with data. All under the umbrella of continuous improvement. Take a bow!

Hope you liked this tongue-in-cheek musical podcast!

Aklak Choudhury from QIP

Join us for another blog soon!

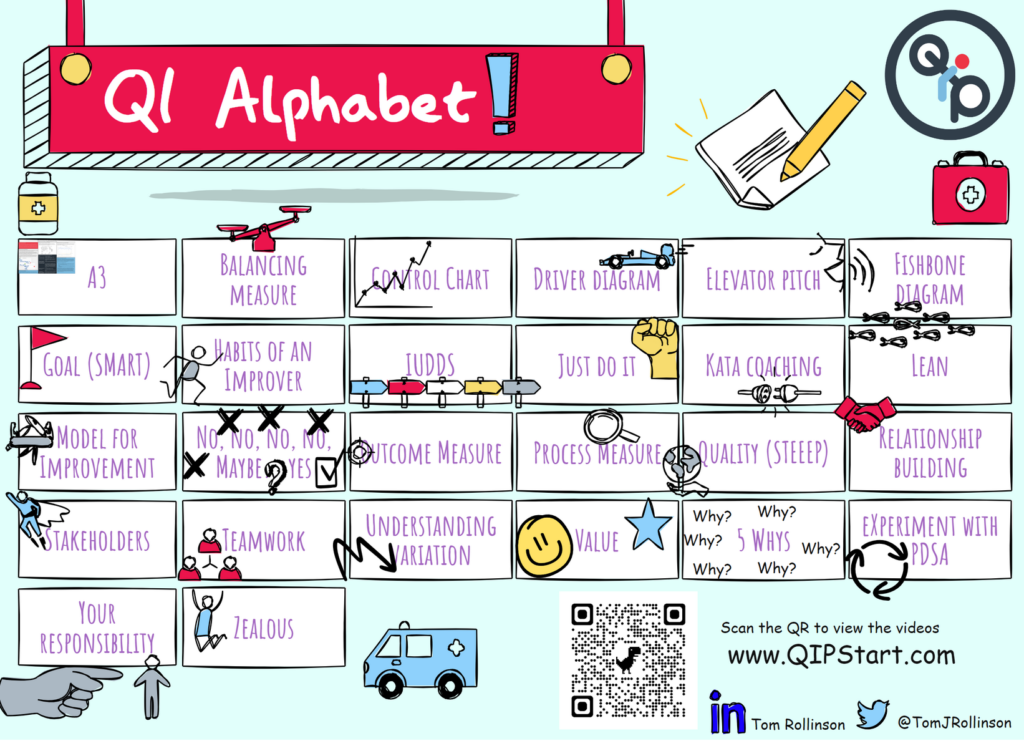

The A-Z of QI

This week we have revisited the QI alphabet; exploring the key building blocks, tools, behaviours and methods used to drive change. This is not to say there are not other vital elements of Quality Improvement, however this is a good starting point to learn.

If you wish to learn more, watch the short clips covering each element of the alphabet: https://qipstart.com/qi-alphabet/

I

Tell us whether this has been helpful!

Tom

Quality Improvement Partners

Join us for our next blog in a weeks time with Aklak

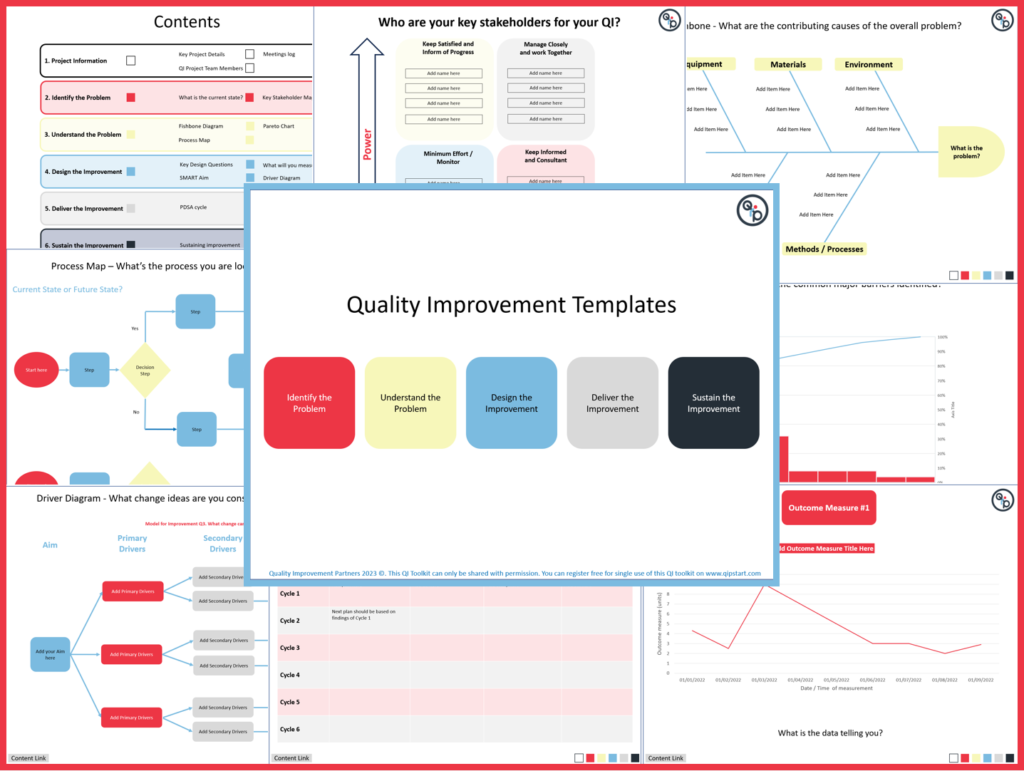

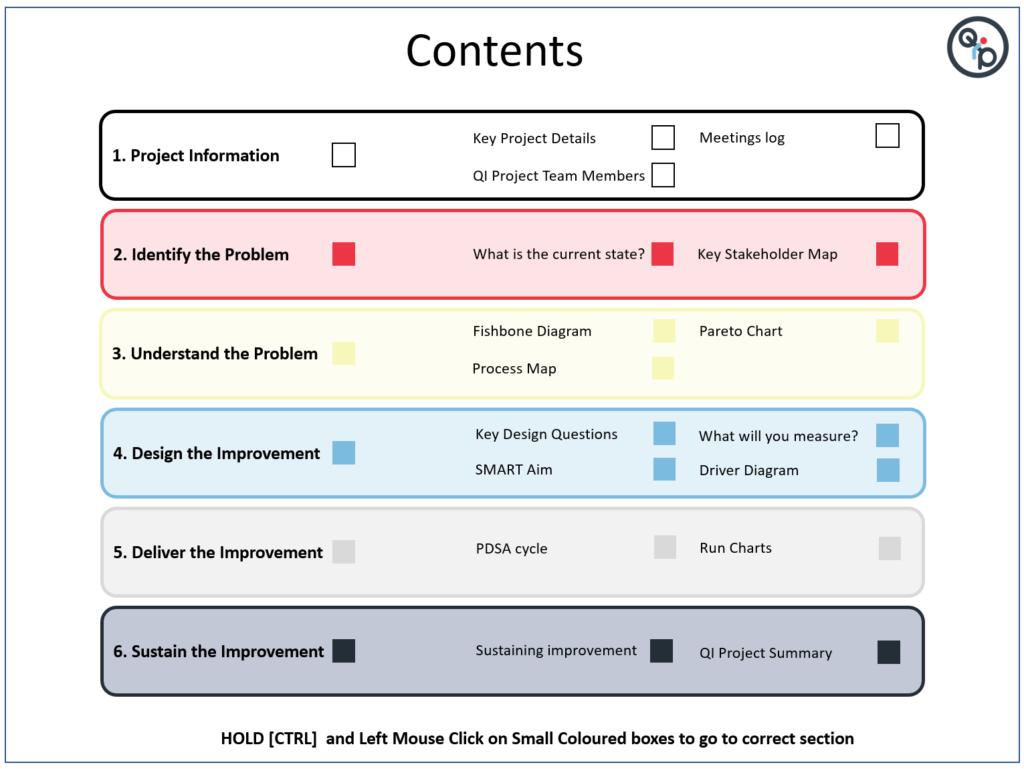

Free QI Toolkit

Register to get your FREE Healthcare fully editable QI Toolkit!

=

Have you every tried to keep all your resources together in one place when undertaking a quality improvement project. Especially when trying to improve the more complex problems within Healthcare. Sure there are plenty of tools out there to help. But rarely do they offer a one-stop solution to plan and deliver your improvement,

Our Quality Improvement Templates don’t just have all the most commonly used QI tools, but also…

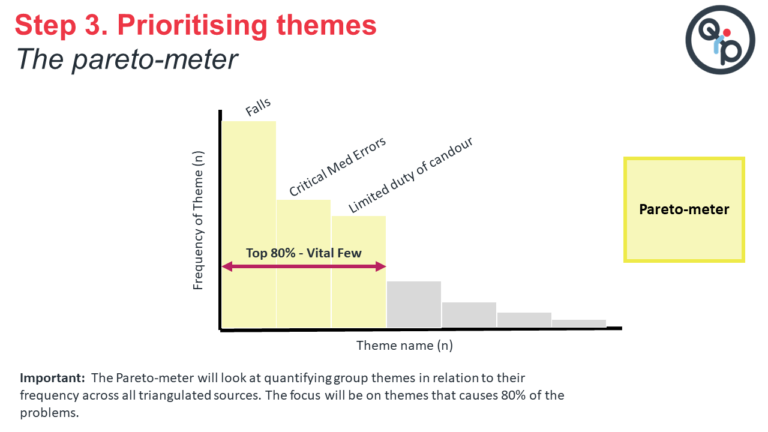

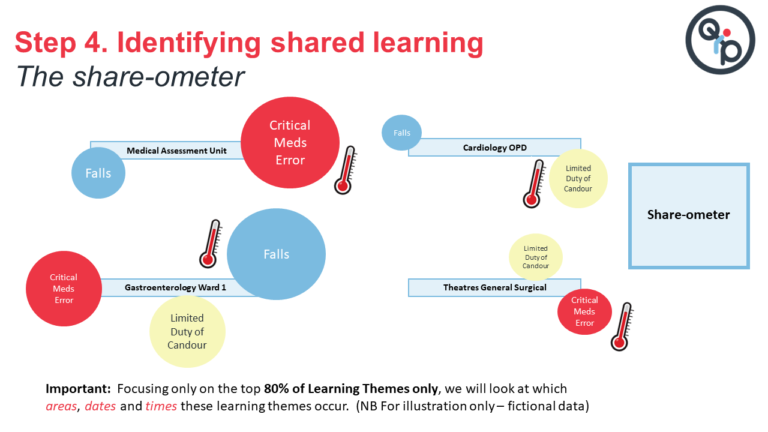

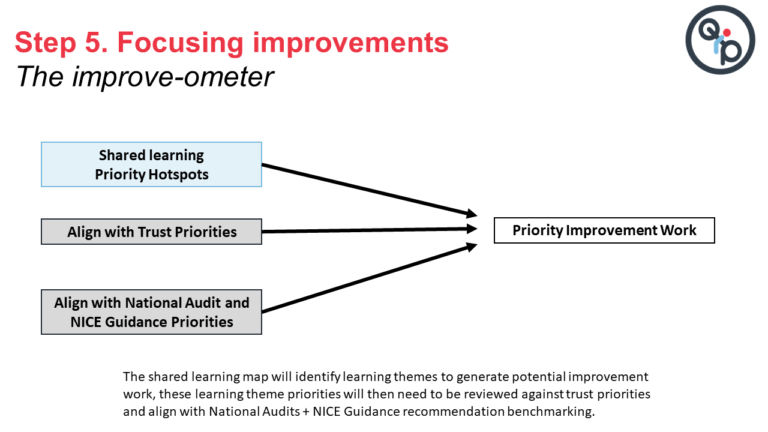

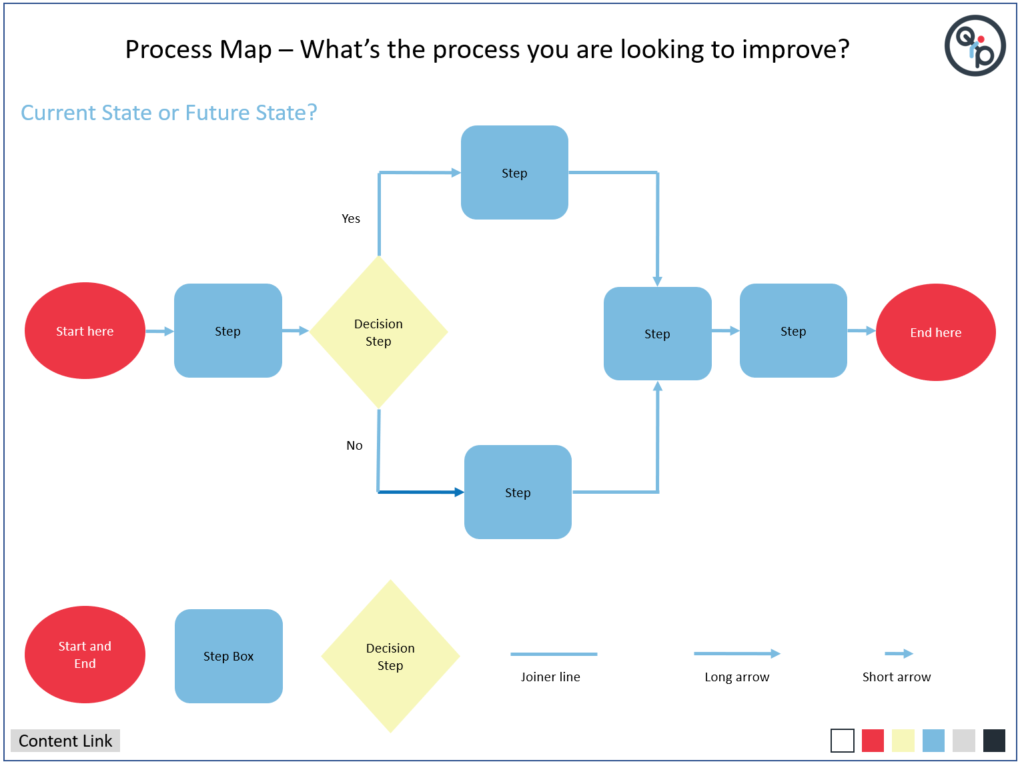

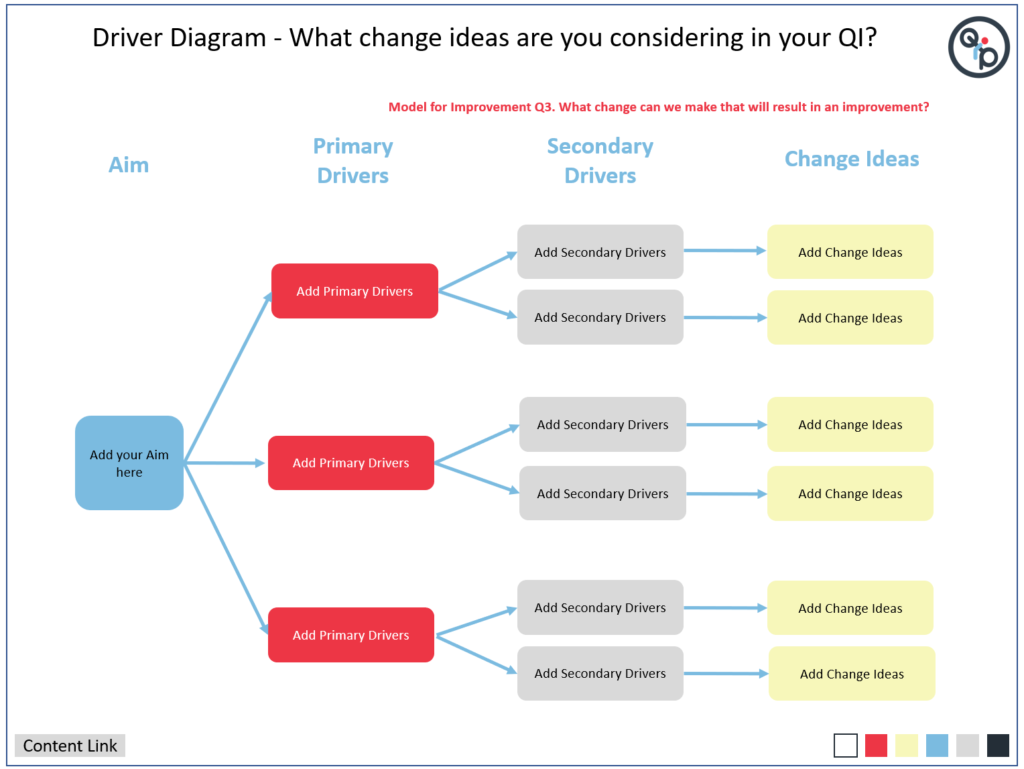

1. They are editable for you to enter information as you progress with your QI. You can create a process map, add and display data to a pareto chart or a run chart. You can describe each PDSA cycle as it happens.

2. They are shown in a logical order as to when you will encounter them. The five stages. Identify a Problem, Understand the Problem, Design the Improvement, Deliver the Improvement and Sustain the Improvement.

3. If you are a fan of Model for Improvement. The slides that indicate the 3 questions and the PDSA cycles are clearly marked in red.

4. The QI Toolkit is kept within Microsoft PowerPoint. Now how helpful is that! You can update the project at your leisure and share with colleagues either by e-mail or on a shared drive.

5. You can move rapidly across the toolkit to the correct section using the colour coded navigation boxes to update information.

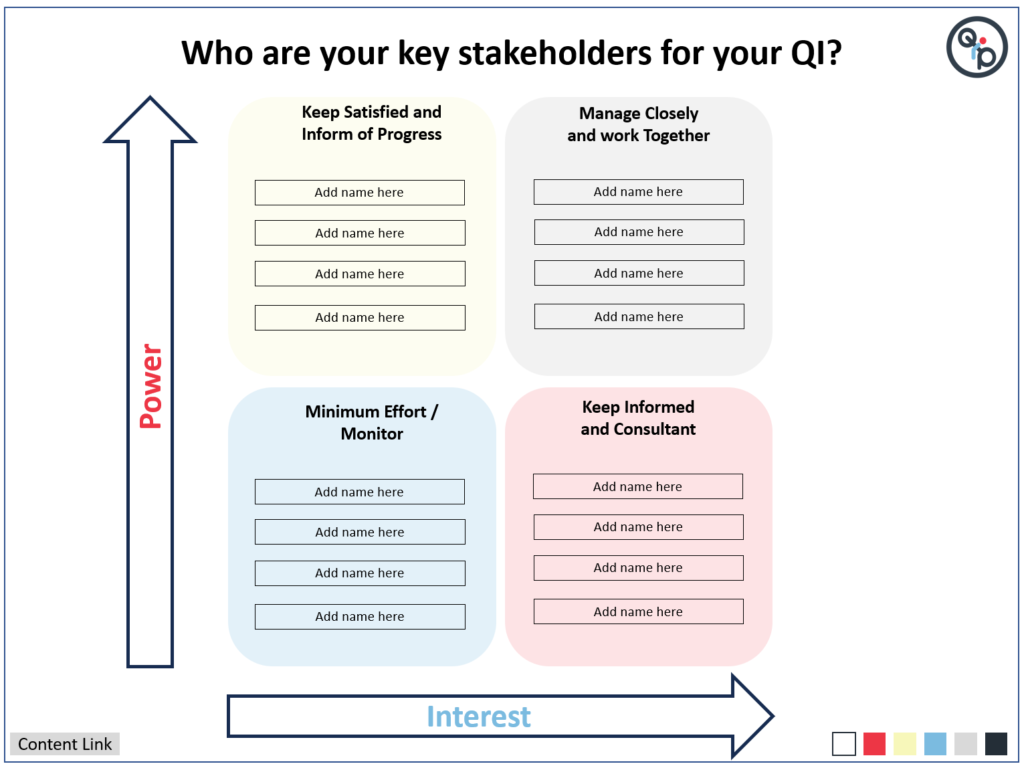

6. The QI Toolkit allows gives prompts and asks many some important questions as you progress with your QI. Such as; what is it like now? who are your key stakeholders? and what are the likely obstacles you may face?

7. The toolkit allows flexibility in what sections you will need to complete. You don’t have to use it all!

8. All the QI toolkit items, including when and how to use them are explained in our Introduction to Healthcare Quality Improvement Course.

In the Deliver the Improvement Section

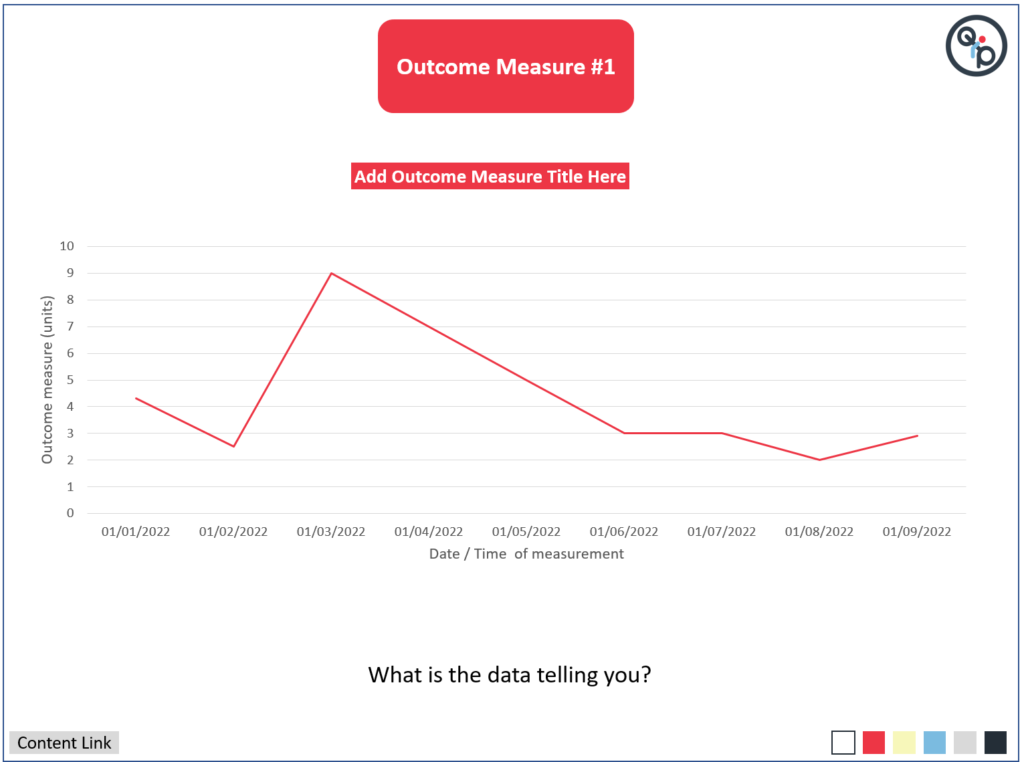

You will be given the tools to record your PDSA cycles and capture the measurements using run charts for outcome, process and balancing measures. Just duplicate the pages to add more run charts!

To change the data on the graph, it is just a simple case of [RIGHT CLICK] and scroll to ‘Edit Data’.

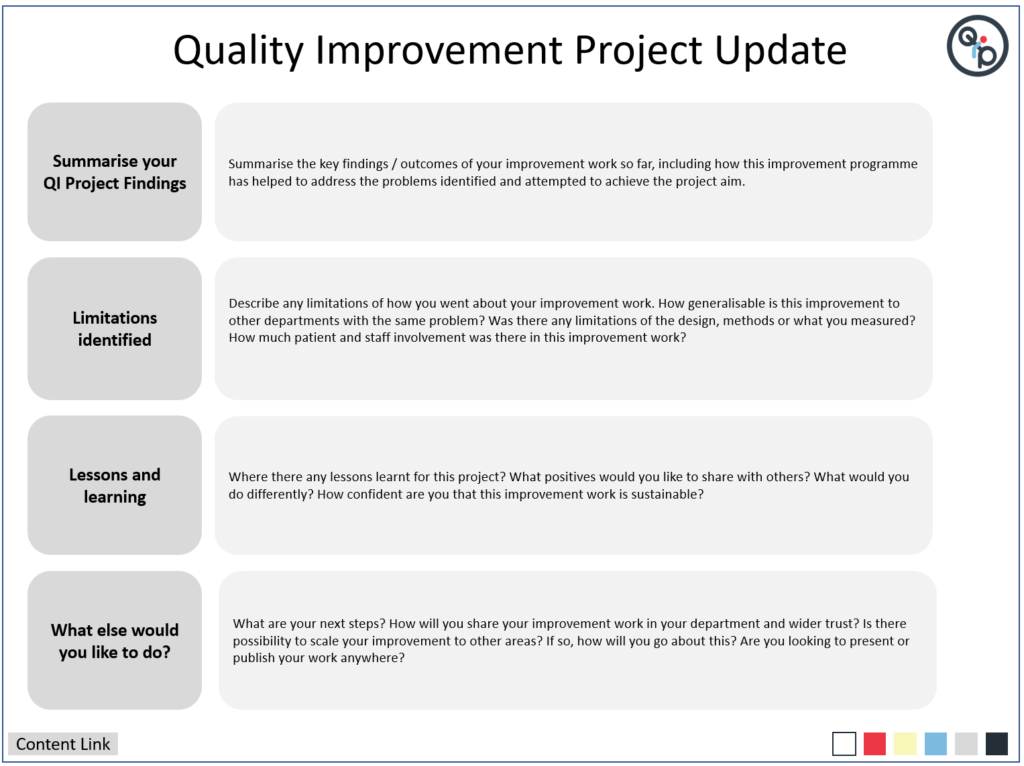

In the Sustain the Improvement Section

You will be asked to describe how you will sustain your improvement and an opportunity to provide a QI project update. this could be used as a handover document or to share with other the progress of your work so far. Remember some projects don’t ever finish as we are continually improving. So an update is all we need, rather then say we have ‘completed’ it

I

Hope you like the QI Toolkit!

Aklak Choudhury

Quality Improvement Partners

Join us for our next blog in a weeks time with Tom Rollinson

Keep calm and pick one

As the field of Quality Improvement grows year on year, new and interesting methods are developed as a way to support improved quality for patients care. Many of these emanate from different industries and have been adapted for health care. The ever growing list of methods can seem confusing when first getting started and creates tension over whether you are using the right one. To help with this, we have outlined a list of methods which are more commonly used, a short explanation and where you can find out more information:

QI Method

What is it?

Breakthrough Collaboratives

Breakthrough Collaboratives, led by the Institute for Healthcare Improvement (IHI), are focused, time-limited initiatives that bring together healthcare organisations to achieve rapid and substantial improvements in specific and pre-determined areas of healthcare quality and safety. Participating organizations collaborate, learn from one another, and implement changes to address common challenges. They use data, structured learning, and peer networking to accelerate improvements. The aim is to achieve significant, large-scale changes that benefit patient care and safety with a focus on spreading successful strategies to other organizations and sustaining improvements over time.

Learn More: https://www.ihi.org/resources/Pages/IHIWhitePapers/TheBreakthroughSeriesIHIsCollaborativeModelforAchievingBreakthroughImprovement.aspx

Clinical Audit

Clinical audit helps to align care and benchmark against known standards, enhance patient safety, and ensure efficient and effective healthcare delivery. Clinical audit involves evaluating clinical practices, identifying areas for improvement, implementing changes, and monitoring progress. Key steps include defining objectives, collecting and analysing data, identifying discrepancies, making recommendations, implementing changes, and continuously reviewing and learning from the process.

Learn more: https://www.hqip.org.uk/wp-content/uploads/2018/02/developing-clinical-audit-patient-panels.pdf

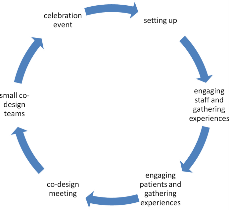

Experience based co-design

Experience-based co-design (EBCD) is a collaborative approach used in healthcare service design, involving patients, staff, and families. It identifies issues in healthcare delivery, hosts co-design workshops to brainstorm solutions and iteratively tests and refines these solutions. EBCD emphasizes a patient-centred culture. It transforms healthcare by integrating patient and staff feedback to enhance care quality and satisfaction.

Learn more: https://www.pointofcarefoundation.org.uk/resource/experience-based-co-design-ebcd-toolkit/step-by-step-guide/1-experience-based-co-design/

Lean

Lean is a management philosophy and methodology that originated from manufacturing and has since been applied to various industries, including healthcare. It focuses on eliminating waste, improving efficiency and maximising value for customers or patients. Key principles of lean include identifying and reducing non-value-added activities, continuous improvement, empowering employees to contribute to problem-solving and creating a culture of efficiency and quality. Lean techniques, such as value stream analysis, 5S (Sort, Set in order, Shine, Standardize, Sustain), and Just-in-Time production are used to streamline processes and enhance productivity. Lean aims to deliver higher quality outcomes while reducing costs and resource waste.

Learn More: https://www.lean.org/explore-lean/what-is-lean/

Learning from Excellence

‘Learning from Excellence’ is a healthcare quality improvement approach that focuses on studying and extracting lessons from instances of excellence and exceptional care within the healthcare system. Unlike traditional quality improvement methods that primarily emphasize analysing errors and adverse events (often referred to as “safety I”), “Learning from Excellence” shifts the focus to understanding and replicating what goes right in healthcare delivery (often referred to as “safety II”).

Learn More: https://learningfromexcellence.com/about/

Learning from Incidents

‘Learning from incidents’ begins with prompt incident reporting and thorough analysis to identify root causes and contributing factors. From this analysis, actionable recommendations for improvement are formulated and implemented, including adjustments to protocols, training enhancements, or equipment upgrades. Continuous monitoring ensures that changes lead to improved emergency responses, while knowledge sharing fosters a culture of improvement. Ongoing training is provided based on incident findings, and protocols are regularly reviewed and adapted to address emerging challenges, ensuring that service remains responsive and effective in delivering critical care.

Learn more: https://qualitysafety.bmj.com/content/26/3/252

Model for Improvement

The Model for Improvement is a framework used to systematically improve processes. It involves asking three key questions: What are we trying to accomplish (Aim)? How will we know a change is an improvement (Measures)? What changes can we make to achieve improvement (Interventions)? And then uses a four-step cycle in an iterative approach to work towards the aim set: Plan (identify and plan changes), Do (implement changes on a small scale), Study (analyse results), and Act (decide whether to adopt, adapt, or abandon changes).

Learn More: https://www.ihi.org/resources/Pages/HowtoImprove/default.aspx

Operational Excellence / Quality Management System (QMS)

A Quality Management System (QMS) is a structured framework within an organization to consistently meet or exceed patient expectations and adhere to quality standards. Quality Management systems are becoming more popular within the healthcare sector and typically consist of several key components:

Quality planning – Collectively agreeing what the overall System (or organisation) wants to deliver and how to do this

Quality Assurance – checks which are put in place to ensure quality of care is being delivered using verified evidence and articulating improvements which have bene made, or areas for further focus

Quality Control – the way monitoring and maintenance occurs to ensure that we know whether the system is achieving the outcomes required

Quality Improvement – the systematic approach used to make tangible change and improve performance

This draws heavily on Lean methodology, adapted for healthcare.

Learn More: https://kpmg.com/xx/en/home/industries/healthcare/operational-excellance-in-healthcare.html

QSIR

QSIR, which stands for “Quality, Service Improvement, and Redesign,” is a comprehensive healthcare approach aimed at improving patient care and outcomes. This is a dedciated set of training courses (depending on your experience) and repository of tools and techniques which can be used to enhance quality standards, streamline service delivery for efficiency and effectiveness, and foster innovative process redesign. Utilising tools such as process mapping and improvement cycles like Plan-Do-Study-Act (PDSA), QSIR promotes a consistent understanding of QI tools which can be used and aims to standardise QI in the NHS.

Learn More: https://aqua.nhs.uk/QSIR/

Six Sigma

Six Sigma is a data-driven approach used for process improvement and quality management across various industries. It aims to reduce process variations and defects, ensuring consistent high-quality outcomes. Six Sigma follows a structured approach known as DMAIC (Define, Measure, Analyse, Improve, and Control) and emphasizes data-driven decision-making, customer focus, and continuous improvement. Trained professionals, known as Black Belts and Green Belts, lead and support improvement projects. The ultimate goal is to enhance quality, reduce costs, and achieve customer satisfaction through empirical evidence and ongoing optimisation.

Learn more: https://www.youtube.com/watch?v=4EDYfSl-fmc&ab_channel=Simplilearn

Toyota Kata

Toyota Kata is a structured improvement and coaching routine developed by Toyota. It involves understanding the current condition, setting a target condition, experimenting, and iterating toward improvements. Leaders provide direction and challenges, while the Improvement Kata and Coaching Kata routines guide teams through the problem-solving process. The PDCA (Plan-Do-Check-Act) cycle is integral to the approach, and a fundamental principle is the respect for people, encouraging collaboration and shared responsibility for continuous improvement.

Learn More: http://www-personal.umich.edu/~mrother/Homepage.html

Virginia Mason Improvement Approach

Virginia Mason’s improvement approach, often associated with the Virginia Mason Production System (VMPS), is a healthcare approach that focuses on continuous improvement, patient safety, and delivering high-quality care. Key elements of this approach include a patient-centric culture, Lean principles, and interdisciplinary teamwork. It aims to streamline processes, eliminate waste, engage staff, and enhance patient experiences. This draws heavily on Lean methodology, adapted for healthcare.

Learn More: https://www.virginiamasoninstitute.org/resource/case-study-bringing-impact-within-reach/

This is not an exhaustive list and there are many other methods which have been used to improve patients care. but we wanted to give a general view of the ones which have been used/work in our experience. However, the next step in picking which one to use can be daunting for fear of picking the wrong one. The evidence on which QI method is most effective is ropey and although certain methods have more documented examples or publications, it is still far from consensus on which one works best. However, it is important to remember that many share underlying principles including:

Identifying the problem which is affecting quality

Analysis of the problem

Setting a clear and specific goal to work towards

Developing a theory of change

Identifying change ideas and testing these changes out in a iterative fashion

Developing interventions to sustain improvements, where needed

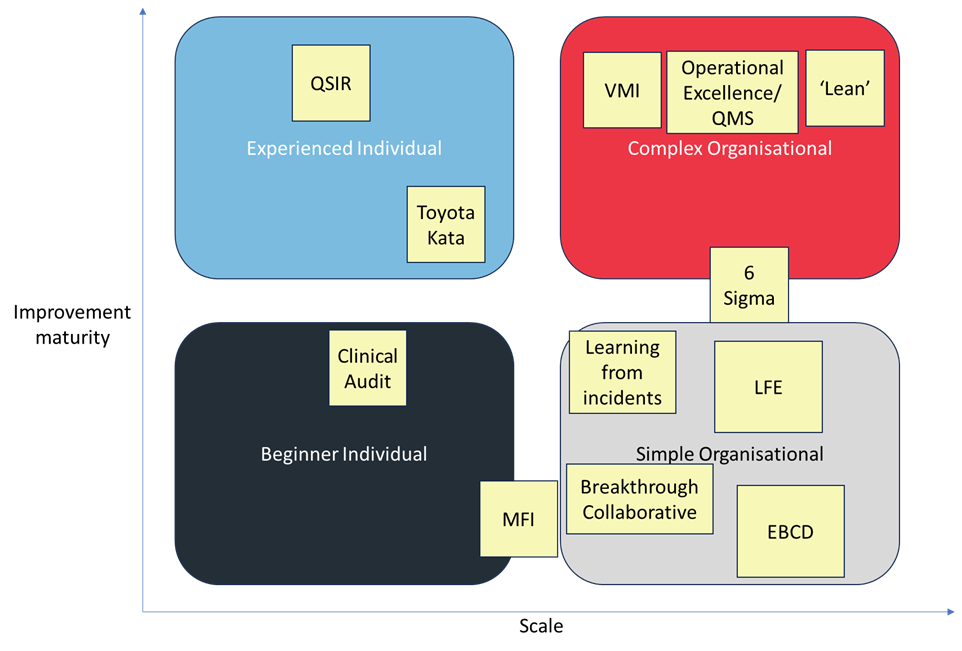

Despite similarities in principles, different approaches may be used depending on the scale of the improvement effort as well as the capability maturity with improvement methods. We have visualised this below and is our view on how this generally works. It would be great to hear if you think differently, so we can learn from you!

In our opinion, the important thing is just pick one approach and get started. Try it out, learn from using it and adapt the approach to what works for you. There will never be a one size fits all which suits your style and circumstances, so the key is take what is useful and adapt in true PDSA fashion.

Cheers

Tom

Join us for the next edition by Aklak next week

Steve from Minecraft discovers Quality Improvement

Hi Everyone, this week we will try something different!

Quality Improvement in healthcare can sometimes feel a bit disconnected to our daily working lives. It can be described in a bland unengaging way, with little opportunity to immerse yourself. Computer games have been with us for years. So why don’t we give Steve from Minecraft a go at improvement. Perhaps we can reach a wider and perhaps younger audience and make everyone curious to find out more?

In the subsequent videos you will see Steve have a go at Model for Improvement and PDSA.

Today is all about discovery…

Hope you enjoy the video podcast!

Aklak Choudhury

Quality Improvement Partners

Join us for our next blog in a weeks time with Tom Rollinson

Page Appeal: The lost art of the summary

How many times have you been in a meeting, with multiple documents which have been expected to be read. You’ve ran out of time prior to the meeting and you are furiously skimming the documents shared at the start to make sure you have an idea of the key issues. You miss out 80% of the content and whilst you are distracted you miss the first 15 minutes of the meeting… . You think to yourself, “I hope nobody asks me a question now as I don’t have a clue what’s going on”.

This is not to say that extended documentation isn’t important and we do advocate, deep and detailed thinking related to complex issues. This long form analysis is key to being able to summarise effectively. However, once the long form doc is written, we can be guilty of stopping there, as the ‘work is done’…Wrong. We are doing ourselves and colleagues a disservice when we slap a 30-page document down and expect them to absorb all this information quickly. This puts a huge strain on our colleagues and also reduces the impact of the message you are trying to deliver by hiding it amongst another 5000 words. Research shows that just listening or reading information is one of the most passive and unproductive ways to retain information. This is compared to audio-visual learning, where using charts, infographics and pictures can increase knowledge recall by 10% more than the former two techniques.

Although producing summaries which are visually appealing may take longer, the wider benefits are often not quantified and does beg the question why we don’t prioritise the extra time to summarise our reports and findings. Making them more digestible, helping to make decisions more effectively.

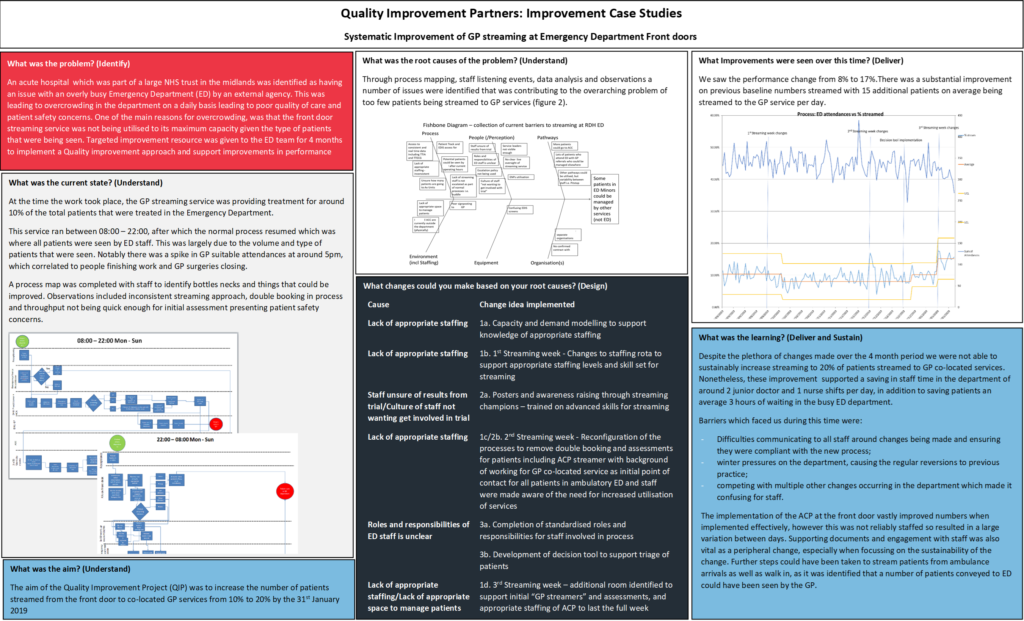

In Quality Improvement, we use multiple approaches for this, but an effective approach which can be used universally is the A3. This is fundamentally a way of thinking, however practically it is (usually)involves several steps which utilises:

An initial phase to understand the problem, the current performance/state and goal setting

Followed by root cause analysis of the issues faced and interventions development.

Concludes with a series of action completion, review of results and agreement on ongoing monitoring (example below)

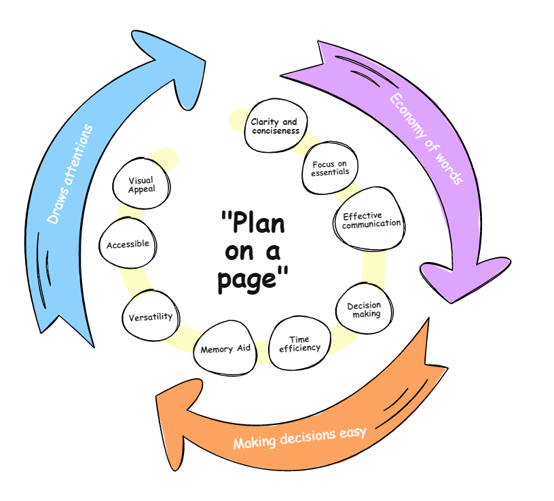

Summarising lengthy reports into one pagers employs a number of tactics to support knowledge recall and information consumption. We have outlined several reasons why using tools like A3 can support any piece of work you are doing:

Economy of words

-

Clarity and Conciseness: Summarising your ideas forces you to distill your thoughts down to their core elements. This clarity and conciseness make it easier for others to understand your message quickly, especially in situations where people may have limited time or attention.

-

Effective Communication: In many professional settings, concise communication is highly valued. A well-structured one-pager can effectively summarise your key points, making it easier for your audience to grasp the main ideas without getting bogged down in details.

-

Focus on Essentials: Creating a one-pager forces you to prioritise and focus on the most critical aspects of your idea. This can help you identify and emphasise the key strengths or selling points of your proposal.

Making decisions easy

-

Decision-Making: Decision-makers often consider a wide range of information sources when making choices. A one-pager can serve as a quick reference point, helping these decision-makers assess the key aspects of your proposal, project, or idea swiftly.

-

Time Efficiency: People are generally busy and a one-page summary respects their time. By providing a brief overview, you demonstrate respect for your audience’s schedules and responsibilities.

-

Memory Aid: One-pagers can serve as memory aids, helping your audience recall and retain the main points of your presentation or proposal. This can be particularly useful when discussing complex topics or during group meetings where many ideas are presented.

Draws attention

-

Accessibility: In some situations, such as grant applications or project pitches, there may be strict page limits. A one-pager ensures you can provide necessary information within those constraints.

-

Versatility: One-pagers can be easily shared via email, printed for meetings, or included in reports. They are a versatile tool for conveying information in various settings.

-

Visual Appeal: A well-designed one-pager can be visually appealing, drawing attention to your ideas and making them more memorable.

Despite the many benefits of using the A3, plan on a page, summary report or any other manner of names which can be used, there can often be barriers to use from my experience. Apart from the time element which can often be banded around, A3’s can very transparent. Lengthy documents can help to hide any issues with progress, therefore summarising performance or project work can be quite revealing and uncomfortable. It also takes practice to do, like anything. Summarising thoughts down into their constituent elements is hard and trying to cram all the original information on to one page can often lead to people just using smaller text. Sitting down and really thinking about what the audience needs to hear or see is key but not always natural. It’s important to remember that you will always have the safety of the longer report to elucidate any details that you think is important.

In brief, summarising your ideas onto one page of paper is valuable because it promotes clarity, efficiency, and effective communication and I would challenge back to say that in the long term will save you time by reducing bureaucracy and having to explain your approach. It helps you focus on the essentials and ensures that your message is accessible and memorable to your audience. So next time you have a lengthy paper to write, I urge you to add an extra half hour to your planning and try to summarise your major thoughts and requirements onto one page and see what the impact is. I guarantee you that you will see the returns on your time investment. Let us know how it goes!

Cheers

Tom

References

Learning Retention: Must-Try Strategies to Boost It Right Away (ispringsolutions.com)

https://www.lean.org/lexicon-terms/a3-report/

Understanding the Science Behind Learning Retention | Reports | What We Think | Indegene

Join us for the next edition by Aklak next week: “Steve from Minecraft discovers Quality Improvement”

Getting to grips with hospital QI – avoid the pitfalls!

In this week’s blog, I would like to share two podcasts describing how as a member of clinical staff you might get started with QI. I was interviewed by Rachel Saville from medical education podcast site MemCast. She also is a Respiratory Trainee Registrar in East Midlands area. Thanks Rachel! I hope you find them enjoyable. There are plenty of tips and insights for new clinicians who are beginning their QI journey. The content and links to the podcasts are described below.

Podcast 1 – Getting started with QI

Defining what the term ‘Quality’ means in healthcare through STEEEP

A definition of QI I like – ‘it’s not all about the methods’

Identifying how you should identify your stakeholders

In the world of healthcare QI, what is a mentor, sponsor and trainee

Podomatic

https://www.podomatic.com/podcasts/medeastmids/episodes/2023-07-21T05_05_47-07_00

Apple Podcasts

https://podcasts.apple.com/au/podcast/getting-started-with-qi/id1485320523?i=1000621883409

Podcast 2 – QI Steps and PDSA

Describing the five stages of an improvement programme – IUDDS

Touching base with Model for Improvement

The essence of PDSA and the common pitfalls

Some useful resources if want to know more…

Podomatic

https://www.podomatic.com/podcasts/medeastmids/episodes/2023-08-11T01_53_58-07_00

Apple Podcasts

https://podcasts.apple.com/au/podcast/qi-steps-and-pdsa/id1485320523?i=1000624135411

Hope you enjoy the podcasts!

Aklak Choudhury

Quality Improvement Partners

Join us for the next blog ‘Page Appeal, the lost art of the summary’ by Tom Rollinson next week.

Change Para-lysis – The ‘nuclear’ option to break down barriers to Improvement in the Ambulance Service

Quality Improvement in healthcare has a long history, but it officially entered the scene initially with the publication of the Darzi next stage review, the rise of the Healthcare Quality Improvement Partnership in around 2008, and the emergence of the NHS Institute for Innovation and Improvement in 2013. However, within this landscape, Quality Improvement in Ambulance Services has faced unique challenges.

Traditionally, Ambulance Services have primarily concentrated on learning from incidents, using them as opportunities to review issues and implement changes. Recent initiatives like Project A and the Ambulance Q network aim to promote Improvement in pre-hospital care while considering the distinct complexities of Ambulance Services.

Nevertheless, the conventional Quality Improvement model has struggled to gain traction in Ambulance Services for several reasons:

Organizational Culture Despite there being a recent pivot to looking at more proactive care and interest in the wider determinants of health, Ambulance Services are inherently emergency-focused organizations. The core mission revolves around immediate response, necessitating command-and-control leadership and a constant state of readiness for crises. The very nature of ambulance work demands a culture of swift, decisive action. The focus on ‘responding’ often overshadows long-term improvement efforts.[1][2]

Professional Standards Unlike Medical and Nursing professions, where Quality Improvement is deeply embedded in professional portfolios, Paramedics have less explicit guidance. While HCPC standards for Paramedic practice do mention Improvement in a general sense, they lack the specificity and emphasis on active participation and data collection seen in other healthcare professions. Paramedic standards hint at the need for Improvement but fall short of providing clear direction and expectations for Paramedic involvement.

Work Environment Ambulance personnel work in a dynamic and demanding environment with minimal downtime. They often lack dedicated time for personal and team development, let alone Quality Improvement activities. The work is characterized by constant movement and high-pressure situations. This leaves little room for contemplating broader changes or engaging in structured Improvement initiatives.[1][2]

So, if we were to draw a force field analysis of the situation, you’d see an epic tug of war with individual staff on one side and a massive, change-resistant squad on the other. It’s like trying to shift the immovable object with a feather duster, and it’s causing frustration, burnout, and even staff exodus.

Having worked in the Ambulance Service and with Ambulance Clinicians, the inability to make change is not through want of trying. They are some of the most competent, versatile professionals in the health care game but as described, the odds are stacked against them. These issues are not going to change overnight, but a movement is underway. Quality Improvement is transitioning from individual endeavours to a systemic approach that aligns with organizational goals and operates as a cohesive unit. This approach, emphasizing quality management systems rather than isolated Improvement efforts, holds promise for overcoming issues, especially the ambulance service barriers, yet is also likely to take many years to achieve.

But before you lay blame soley at the “System” you find yourself in, imagine a world…Where you didn’t have to rely on others to make change for you; where you were able to assume control, taking tiny steps towards “Better” for you and your team? Maybe there is a way?

In the challenging environment of Ambulance Services, where the need for Quality Improvement is paramount but often met with resistance. I think we need to think differently about micro-changes repeated every day, so that Improvement becomes reliant on habits, rather than traditional rigid methods. This is not a tried and tested approach, but maybe its worth a try. The principles of “Atomic Habits,” as outlined by James Clear, can provide a practical framework for driving and sustaining positive change. Let’s explore how these principles can be applied effectively:

Make it Obvious: In the context of Quality Improvement in Ambulance Services, making the desired change obvious is crucial. This involves clearly defining what needs improving and setting specific, measurable goals. For example, rather than a vague goal like “improve patient care,” it could be “try to reduce time on scene with patients by 5 mins per patient or make sure your vehicle is fully stocked before leaving your shift.” This clarity helps Paramedics and staff understand the focus and direction of their efforts.

Make it Attractive: Attractiveness plays a pivotal role in habit formation, associating action with positive emotions or rewards. In the Ambulance Service, making Quality Improvement attractive could involve gaining support from organizational leaders and emphasizing the positive impact on patient outcomes and job satisfaction. Rewarding and celebrating successful efforts can make the process more appealing, motivating individuals and teams to engage actively.

Make it Easy: Paramedics and staff in Ambulance Services have demanding schedules, leaving little room for additional tasks. To overcome this, the habit of Quality Improvement must be made as straightforward as possible. Simplify processes and provide tools and resources that facilitate Improvement initiatives. For instance, create user-friendly templates for documenting improvement projects, or introduce digital platforms that streamline data collection and analysis. I previously re-purposed an existing app which allowed all non-ED pathways contact details to be stored in one place, which instantly increased use of these pathways as they were easily accessible with no extra cost.

Make it Satisfying: One of the keys to habit formation is the sense of satisfaction that comes from completing a habit, even with modest gains. In Ambulance Services, implementing Quality Improvement projects can become satisfying by showcasing individual and team progress through data or patient feedback. Recognize those who actively engage in improvement efforts. Seeing the positive impact of their work on patient care and outcomes can be a powerful motivator. The opposite approach could be taken for unwanted behaviours, especially through feedback loops to support people to make the right decisions and understanding their reasons for current unwanted behaviours.

If there was one I might add in this situation it would be…5. Make it Important: In the context of Paramedic work, emphasizing the importance of Quality Improvement is essential. Link Quality Improvement to the evolving expectations in the profession and the broader healthcare landscape. Show how it aligns with the organization’s mission and vision, regulatory requirements, and the ultimate goal of providing the best possible patient care. We need to help others understand that Quality Improvement is not just a “nice to do” but a fundamental aspect of everyone’s role.

By applying the principles of Atomic Habits to Quality Improvement efforts in Ambulance Services, it may be possible to take repetitive microscopic steps towards Continuous Improvement. Rather than expecting individual Ambulance Clinicians to initiate and manage Improvement projects independently, the focus shifts towards a collective effort, supported by organizational structures and leadership.

In this way, Quality Improvement becomes an ingrained habit, a part of daily practice and a shared commitment. It moves from being a daunting challenge to a routine aspect of Paramedic work, ultimately leading to better patient outcomes and a more resilient healthcare system. So if you’re reading this, think about how you can help your teams by applying some of the atomic habits above or how you as an individual might develop Improvement habits using these tiny tools.

Let us know how this works for you

Join us next week for… “Getting to grips with hospital QI – avoid the pitfalls!” Podcast

References

-

Hobbs L, Devenish S, Long D, Tippett V. Facilitators, Barriers and Motivators of Paramedic Continuing Professional Development. Australasian Journal of Paramedicine. 2021;18:1-7. doi:33151/ajp.18.857

-

https://www.paramedicpractice.com/features/article/the-paramedic-profession-disruptive-innovation-and-barriers-to-further-progress

Are you seriously expecting me to change the world in four months?

An experience of an F2 doctor trying to do QI in 4 months…

This might seem a bit familiar when you are starting out as the new doc on the block in a busy hospital department. You are daunted by the prospect of learning the clinical ropes. You know you need to get on with a quality improvement project, because your curriculum says so. But… you hardly know anyone or how things work around here.

Your consultant supervisor smiles innocently and asks what QI project you would like to do. You smile back and say something remotely intelligent, knowing you just lifted this off the departmental induction pack 5 minutes ago. Really you were hoping that the consultant would come out with the improvement project ideas. Surely they would be more aware of what the problems are in their department, right? But no, it is down to you.

So off you go, wondering what improvement work is out there. Asking random people, hoping someone will help you on your quest to do improvement work. That one-hour QI intro lecture at the beginning of the year seems a distant memory.

In the first month, most of your time is spent trying to keep your head above water. You often feel overwhelmed. There is just so much to know and learn. Trying to start a QI project seems less of a priority when compared to the clinical work pressure. You want to be safe for your patients… You will think about QI later. A form of ‘duality’ occurs in your mind. The need to separate the clinical work to that of the improvement work. Yes, to compartmentalise will help you cope and get through the day. You will leave the ‘QI bit’ to Thursday afternoon when the staffing is better and it is quieter.

You become more aware that you are a now a small cog in a team you are not familiar with. Some staff have been there for years, some have just started, just like you. A few weeks pass, you are getting to know all the players; who is important in the team, who can help and who to avoid. But as a relatively new doctor, you don’t feel safe proposing any improvement ideas to the team. How will they react to your idea? Will you end up looking foolish amongst your peers? Can you speak up to your consultant surgeon with many years experience and say there might be a problem worth fixing? Do they even care what you think? Do you feel psychologically safe enough to bring this up??

The 4-month rotation mercilessly moves on. A few on-call weekends pass. It is already week six. Not much has happened on the QI front. Some ideas form, but nothing concrete. So much for the flying start… a few more weeks pass. You begin to feel more comfortable within the department, you know your role within the team. Importantly, you are now developing relationships with your ward nurses, physios and pharmacists. One or two are now your friends.

A few more weeks pass. The clinical work pressures remain, but you are performing well clinically, you have formed an identity and feel valued for your work. You begin to revisit your need to complete a QI project. This is your last rotation for the year, your ARCP assessment is just around the corner. You wanted to make a meaningful impact on patient care through QI, but now there is not enough time. Perhaps you should focus on something that is more manageable? Try to keep the improvement small, the change ideas simple. Maybe focus on some ‘low-hanging fruit’ QI. Possibly a stool chart PDSA, or perhaps a handover sheet for the morning surgical meeting. You could print the sheets out yourself. No need to get the wider team involved. The QI might not sustain after you leave, but at least it is something you can show at ARCP. You will try and do a ‘proper’ QI next year.

The 4-month rotation is now up. The QI project done. A couple of PDSA cycles mashed together. The time-sensitive ticking clock of QI negated, just in time for ARCP. But the QI ticking clock has now been replaced by another type of ‘tick’. The all too familiar QI tick box

The above story is fictional. It is based on the findings of a qualitative MSc study exploring how the social learning environment influence how trainee doctors engage with improvement work (Choudhury 2022). F2 doctors, educational supervisors and trust improvement specialists were interviewed.

We can explore the challenges that F2 doctors face immersing themselves within a new clinical department through the lens of Tuckman’s team building model (Tuckman 1965). The model described a number of stages for team development.

Forming – a new team is formed with rotational doctors joining every 4 months. Tasks and roles are not always defined.

Storming – Individual boundaries become contested and conflicts can occur. There is often jostling for position for new staff.

Norming – Members of the team resolve their differences, with greater acknowledgement of other team members strengths and weaknesses

Performing – The team becomes functional, works effectively and efficiently to complete tasks. There is high development of roles and responsibilities

Adjourning – This phase does not always occur. Especially for junior doctors, as they are often not there long enough. Can lead to missed opportunities to celebrate successes or even mourn their departure.

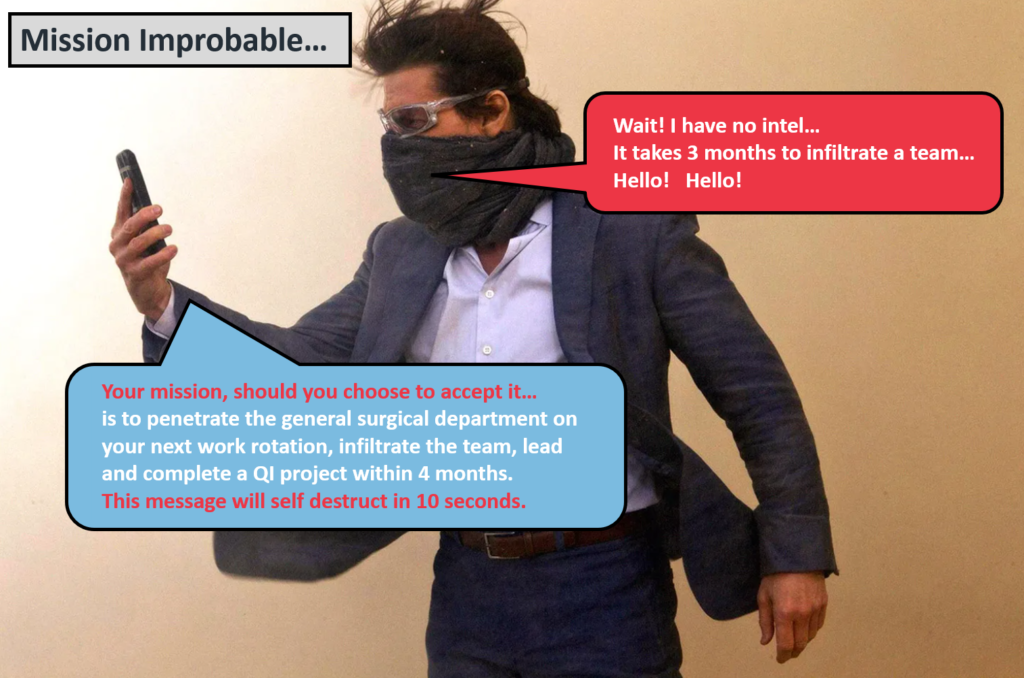

The illustration below highlights the strain for F2 doctors when faced with the competing priorities of performing clinical duties and improvement work all at once during a four-month placement.

So what does this all mean?

These F2 doctors describe an uncomfortable feeling of a clock ticking down with growing pressure to complete a piece of improvement work within a four month window. This is challenging for an established member of a departmental team, but near impossible for new members such as F2 doctors.

So why the mad rush to finish the QI project in 4 months? We know that complex problems can often take many years to improve often under the umbrella of continuous improvement. A more systematic sustainable approach to improving quality of care, with no obvious start or end date to the improvement programme.

Could there be extrinsic drivers to explain this behaviour? F2 doctors can describe in detail the scoring systems for QI and clinical audit with their relative weighting for shortlisting. Just as an example, the specialist interview shortlisting for physician higher training for QI attainment suggests to score the top prize of 5 shortlisting points, you need cover:

“all aspects of two [PDSA] cycles where you can demonstrate a leadership capacity by supervising other members of the team.”

Wow… that would be an impressive feat considering it takes three months to get your feet under the door in a new department! Did I mention, the F2 doctor will also need to lead and inspire these departmental old-timers in a QI programme… I hope they had all their leadership experience front-loaded in medical school.

Training curricula for doctors can also be overly prescriptive in what constitutes ‘exemplary standard’ of QIP. Let us take the example from physician core training assessment tool for QI.

“QIP topic related to an important clinical problem, detailed and exhaustive methodology applied, appropriate presentation of results with correct interpretation and comprehensive conclusions. Plans for future direction of QIP highlighted. An exemplary QIP.”

All of the above in 6-months for internal medical trainees, a lot to do and not a mention of a team approach to QI anywhere…

So have we set-up our new doctors to fail? To achieve the unachievable? Have they signed up to Mission Improbable? The educational and competitive career progression mandate has led to trainees seeing QI as a hurdle to overcome and not seeing improvement for what it should be, an opportunity to improve the patient experience. It is in fact us who have led them to the ‘QI tick box’. That short term unsustainable ‘low hanging fruit’ piece of QI work done in haste, that has little impact on patient outcomes.

So what could we do differently?

Certainly there is recognition for change. It was encouraging to see the recent publication from the Academy of Medical Royal Colleges and their take on assessment of QI published in 2023. The document states trainees are not required to have done entire projects from start to finish (phew!), and there was no need to lead a project at any stage of training (double phew!).

This change in direction can be a catalyst for major quality improvement reform for doctors in training. It is badly needed. NHS organisations need our rotational trainee doctors to support the often complex challenges facing many trusts. They are the ones seeing the problems daily, why should they not be part of the response?

We can help our trainee doctors by:

Promoting at trainee induction the correct mindset for improvement, specifically, that meaningful QI participation in results in better patient experience

Identify departmental improvement work early in their four-month rotation. They should not be searching for it

Allow trainees to remain on improvement programmes for greater than four months when feasible, if not possible, ensure mechanisms for handover of their QI work

Create multi-disciplinary coaching and support groups for rapid onboarding of new doctors through a departmental QI Faculty

NHS trust corporate teams could ensure local departmental improvement work is recognised and appropriately supported rather, rather than focus solely on executive driven large scale programmes